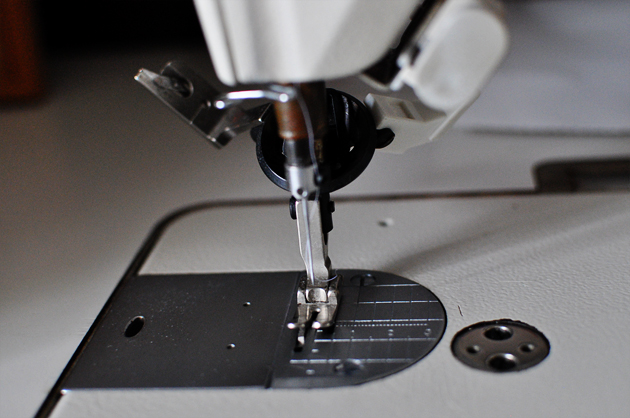

As I wrote in this post, I bought a new sewing machine! It is a Juki industrial sewing machine, DDL-9000SS with CP160 Servo Moter. I thought I’d write a review – I’ve only been using it for a less than two weeks, so I still have a lot to learn but here are my initial thoughts:

As I wrote in this post, I bought a new sewing machine! It is a Juki industrial sewing machine, DDL-9000SS with CP160 Servo Moter. I thought I’d write a review – I’ve only been using it for a less than two weeks, so I still have a lot to learn but here are my initial thoughts:

Model: 9000SS

I had the hardest time deciding whether to go for one of the Juki’s older models, the 5551, 5570 or 8700. They were cheaper, and I heard that industrial sewing machines last for a while, even the older models if you take a good care of them. But at the same time, I’ve heard that Juki no longer produces parts for older models, so if it broke, I would have hard time finding the necessary parts. This was a concern to me since I know nothing about fixing sewing machines. I am terrible with anything mechanical. I don’t even know how to change a light bulb!

That is most of the reason I went for the newest model from Juki, the 9000 series.

9000 is a direct-drive machine, so the head of the sewing machine is very heavy. The dealer took the machine to the second floor of my place, but because of the narrow stares, he had to take the head off the machine and carry the table and the head separately.

Why Juki?

No particular reasons, except that I have a Juki serger. I thought I’d match. I think Juki and Brother are the two major industrial sewing machine manufacturers, and I’ve seen the designers use Brother industrial sewing machine on Project Runway. I got Juki because if something happens to my machine, I can contact one manufacturer, instead of two different ones 🙂

Speed

It goes up to 5000 stitches/minute. If it is running in the highest speed, it is so fast! I am concerned that I will break a needle because it is that fast. Adjusting the speed is very easy with this machine. It is almost like home sewing machine. You can adjust the speed with the foot pedal, but also adjust the maximum speed at the thing on the computer panel on the right side of the sewing machine. I usually set it in the medium, but it still goes very fast.

Motor

During the search for the industrial sewing machine, I learnt that there are two different motors for industrial machines: clutch motor and servo motor. Mine has servo motor and I am very pleased by that. I hear that it is very difficult to control the clutch motor, it is like driving a stick shift. I haven’t even driven a stick shift before (there are two different driver licenses in Japan! stick shift license and automatic one), so naturally I went for servo motor. With servo motor, machine works just like home sewing machine. It is very easy to control the speed.

Automatic thread cutter

I love this feature. By pressing the pedal deep on the ankle side, the machine automatically cuts the tread short and lifts the sewing foot. I did not know what a time saver it was until I started using it. It is also nice not to have a bunch of thread cluttering your sewing table.

Needle

Industrial sewing machines use different needles from home sewing machines. It uses a needle called DBx1. The shape is different, as it is all round, but has a dent on the side shaft. I struggled a bit trying to change the needle. It is really important to have the dent on the right side, and the top of the needle touches the ceiling of the place you insert the needle. For some reason, I could not get its head touch the ceiling even if I pushed, so I ended up tightening the screw for the needle without properly inserting the needle. This caused the bobbin thread stitch to skip, and I had to redo it. I feel like the needle breaks much easier with the industrial sewing machine, with small things, like touching the hard plastic part of the invisible zipper or something. I get nervous every time I break a needle until I find every broken piece. If it gets in the bobbin case or somewhere near down there, that will damage all those metal parts which will eventually cause the need for sewing machine repair.

Where I bought it

I bought my machine from this guy. He runs the second hand industrial sewing machine shop, sells sewing notions online, and sells shrimps and oranges. That’s so random. He said he used to own a sweatshop, but because many brands use factories overseas for cheaper labor costs, he had to close down his factory. After the close-down, he started a business of buying second-hand industrial machines from factories in Japan, repairing them, and selling them online. His shop is located in Kumamoto, Kyusyu island, but he delivered my machine himself, set it up in my studio, and taught me how to use it. I am very pleased by his service. Other second-hand industrial sewing machine dealers did not deliver by themselves, rather they use a regular shipping company like Yamato, so when the sewing machine arrive you will have to know how to set it up or have the sewing mechanic come in. After my sewing machine’s break down, I wanted little to do with machine trouble. So I do recommend this place. He only speaks Japanese by the way.

Light

Unlike the home sewing machine, there is no built-in light. Thankfully my dealer attached a florescent light right above the sewing foot area, which makes it easy to see. It is just a small thing, but it counts!

I have a lot more to say, but will save it to another post!

4/23/2014 UPDATE: Here is a short video of Juki DDL-9000ss so you can see the machine in action!

Beijing Trip

Beijing Trip Currently on My Sewing Table

Currently on My Sewing Table Mend & Make FABULOUS Book Feature

Mend & Make FABULOUS Book Feature As Seen In…A Beautiful Mess

As Seen In…A Beautiful Mess

Kathleen says

The other neat feature your machine has that does not come standard, is a turret foot. Very handy, I just got some for my machines that can take them. Yours is a nice solid machine; you’ll get many years of enjoyment out of it. I have a DLN 9010 (needle feed) that is similar. My other Juki is a 1541 walking foot. Generally, you don’t need to worry about age of a Juki. These are nicely engineered machines, designed to use standard parts so it would be unusual that parts would be unavailable. My other machines span a variety of makes. My favorite is my Adler 271. It’s older than yours but the mechanisms are more elegant, no other way to describe it. Parts for it are insane expensive but unless one does something really really stupid, it is hard to break an industrial.

Note: sweatshop is derogatory and should not be used as a synonym for sewing factory. I run a sewing factory (kind of, more product development than anything) and my shop is neat, clean, comfortable, safe and with the latest in industrial equipment. I pay a starting wage that is 120% over minimum wage. Mine isn’t a sweatshop. I’ve worked hard to provide all of this; I went without help for a long time (over 10 years) because it mattered a great deal to me to provide a nice working environment and good pay to employees when I eventually hired them.

Chie says

Hi Kathleen! First I just want to say that I am so honored to read your comments on my little blog! I have been reading your blog for a long time. When I first came across with Fashion Incubator, I spent hours and hours on your site, reading every single one of your articles!

I read your review on your industrial sewing machines, and it was very helpful for me in deciding to purchase my sewing machine. I have not found any Adler industrial sewing machines in Japan. I found Juki, and Brother and some Mitsubishi, but never came across with Adler.

I was lucky to get a machine with turrent foot (I didn’t know what it was called) already installed, because the previous owner of the machine was a sample maker. My dealer asked me before delivering the machine whether I wanted it to be replaced with a single foot, but I asked him to keep it. I have an invisible zipper foot, regular foot and rolled hem foot installed and it is very handy to have three of them ready to be used, instead of installing them with screw driver every time.

Sarah says

I would love an industrial machine, I used one at the place I use to work, a brother I think it was but very old and not well looked after either, but lovely to work with!

Glad your happy with yours. juki has a good name and I think I would go for this make too if I ever buy one ( I hope to at some point) I’m quite interested to hear about the servo motor too it’s not something I’ve came across before. Thanks for share your thoughts on it, look forward to hearing more 🙂

Chie says

Hi Sarah! Before looking into purchasing an industrial sewing machine, I didn’t know there were any differences in motors. I first made an inquiry to a dealer about a machine with clutch motor, because that was the cheapest machine on sale, but after a little bit of looking into, not only the lack of speed control but also the noise can be a problem for me if I were to purchase a machine with clutch motor. I hear that as soon as you turn the machine one, it makes a noise like plane taking off! I live in a town house with a neighbor facing right next to us, so I’m sure I would have heard a lot of complaints!! I am so happy with servo motor. It is very smooth, and when you turn off the machine, the noise is barely noticeable!

Ramona says

I have been searching the web for reviews of the Juki and find so little. It’s distressing. Thank you for posting your thoughts on your machine. I’m about to purchase a Juki, but I’m having a hard time choosing a model and do not have a local dealer. Your comments have helped. Thanks!

Chie says

Hi Ramona, I am glad that my review was helpful! I did run in to the same problem when I was looking for a review for a specific model. For instance, I could not find many reviews on 9000SS, which is the one I bought. Anyway, I am planning on writing more reviews on the machine later, so please keep checking back:)

Thewallinna says

Thanks for sharing the review! Now I am more and more convinced that an industrial sewing machine is much better and worth the money rathern than any fancy electic sewing machine!

Chie says

Hi! I love my new machine! I think it depends on what you sew, whether an industrial machine is worth it for you.. For me since I never really use anything other than straight stitch, it was a great purchase, but if someone wants fancy decorative stitches, then maybe electric machines might be better suited for them! 🙂

Ginger says

Thanks for the review! I’ve never used an industrial model, but I’m really interested in them.

Chie says

Hi Sonja, I think you would LOVE an industrial machine! It has cut my sewing time so much, I regret for not purchasing it sooner.

Shirley says

Hi! I came across your blog through the luvinthemommyhood maternity round up (you posted a paperbag maternity skirt on DIY maternity). Then I started reading your posts on adoption and your little girl and I just wanted to say I love your blog and I’d love to hear how the adoption process goes for you. It sounds like whatever your family looks like one day, it’ll be loving and happy.

I guess to be more related to this post: I’ve never bought a sewing machine (I use my mother’s old one for everything) but if I ever decide to invest in sewing as a small business I will definitely consider your review!

Chie says

Hi Shirley! Thank you so much for your comment! Speaking of adoption, we JUST got approved as adoptive parents and now in the waiting period! I am planning of sharing more in the future post. Thank you for reading my blog, so encouraging to read comments like yours <3

Amber H says

I have a Juki machine myself, with the auto cut thread feature! One thing i’ve learned is that sometimes when sewing it doesn’t want to catch the bobbin thread, so I always use a leader piece of scrap fabric to start sewing.. it’s easier to snip that off than to start sewing and find that it didn’t catch the bobbin thread for the first 1.5 inches of my edge.. really annoying!

Mike Muromoto says

Konnichiwa Chie-san. I hope you can help me with a question relating to the table set up of the Juki industrial machine. I bought an older used Juki DDL 55 series machine for very cheap, and need to transport it home. This requires removing the machine head from the tabletop. I have not been able to find any info on the web about how the machine head is attached to the table, other than it uses Euro hinges. I know the DDL has an oil pan reservoir that is recessed into the tabletop, and the machine head sits on the oil pan, hinged to the top. Your blog says the person you bought your machine from had to take the head off the table to carry it upstairs. Were you able to see what he did to remove the head from the table? Was it a lengthy/complicated process, or done quickly? Would you know what tools he used? I have asked the seamstress who I bought the machine from if she knew how to remove the head from the table, but she said the machine came fully assembled when she got it, and she does not know how the head is removed. My web searches have turned up replacement tabletops, but no instructions on how the head is mounted. I saw your blog and thought you might know from your experience. I would appreciate any info you can send me. Arigatou gozaimasu. Mike in Hawaii. PS: Your English is excellent.

Victor Milla says

Mike, machine head is not attached to table top, no need for tools to take down, just push the machine head back realease the V-belt and lift the metal hinges just rest on the rubber hinges. that is it, if you are going to move the machine drain the oil from pan through the screw at the bottom of the pan. if clean save it to re use if lightly dirty drain thru and old tshirt, if it does not look good at old change for new sewing machine oil.

if need more advice write to my E-mail I will be glad to help.

Janet S. Larson says

Hello, Chie!

Your review of the Juki 9000 is the only practical one on the Internet – Thanks! I just purchased one and know that one foot I will be needing is the equivalent of the Blindstitch foot “D” #412-3804 by Viking. The left side of the foot is slightly raised as compared to the right side. I’m sure someone has manufactured this kind of foot, but probably under a different name. Any suggestions on what direction to go to track this down?

Thanks so much!

Janet

http://www.jsues.com

Chie says

Hi Janet! Thank you for your comment. Unfortunately, I have no idea where you would be able to find the foot, as myself only has three for my industrial sewing machine. I have regular foot, invisible zipper foot and rolled hem foot. When I need other foot like blind stitch, I use my home sewing machine as it is easier to switch between the foot for home sewing machine. I have to unscrew the foot for my industrial one, so I try to avoid that. Thankfully I have a torrent foot, so I can switch the three back and forth, which comes really handy! I hope you will find the food you are looking for.

Janet says

Thanks so much, Chie – I’ve been wondering about how much I’ll still need my standard machine. Your comments are helpful.

Chalky says

Janet,

You can start here: http://www.shop.heavysew.com/Juki-DDL-9000_c151.htm

If you can’t find your part there, call the dealer you bought your Juki from and ask for the Blind Stitch/Hem presser foot. You can also try any of the Juki dealers online: Sunny Sewing, Keystone Sewing, AllBrands, SewingGold.com, etc.

I know the Juki industrials take generic parts and accessories which are interchangeable with Singer, Brother, Consew, Yamata and other brands. A dealer would be your best bet if you cannot locate the part online.

Janet says

Thanks, Chalky. I’ll check out those options. I’ve been in contact with Sharp, but they weren’t much help.

Nick says

Hello,

I have so many questions to ask I feel like this machine is a complete mystery and it’s been a joy and pain figuring things out. I am very familiar with Juki machines but this is a whole new ball game of problems that I haven’t been able to figure out from prev Juki machines I had before. Have you tweaked this machine around to accommodate different fabrics and weights? I’ve had the same set up as you for the last three years now and I’ve been able to change settings and such with no problems but now I’m running into so many problems with tension both top and bottom and moving into larger stitches past 3 has been more than challenging these days. I used to be able to sew very light sheer silks to midweight lamb leather and furs with nylon treads but now I can’t get it to do anything with nylon anymore. In the last three months I’ve been trying to find solutions all over the internet and sewing machine repair shops (I live in NYC by the garment district..you would think it’d be so easy to find help but this machines have never even made it to any of the stores or repair shops before so it’s a complete mystery. I’ve called in my old guy for my old machine when I used to get them tuned up but he has no idea about the different mechanics of the machine and what’s really causing all my problems as of late. I bought it several years ago from Carolina and the place has now gone out of business since so I’m at a lost on where to turn for help. I guess my question is if you’ve run into any simmilar problems with the machines this far.

Tina says

Hello.. actually I’m looking for the quilting machine that have high durability and high capacity for industrial. I was bought various quilting machine with different brand such as singer, toyota and janome and it wasn’t tough enough for the industrial capacity. Can you give me a suggestion? and how about the Juki that you bought.

Thank you.

Chie says

Hi, I am sorry, I have no idea about quilting machine. I don’t quilt at all. Sorry!

Jim says

Industrial Quilting machines are a much larger leap from hobby to commercial than straight stitch machines. You can look at Gribbits International and Atlanta Attachments to get an idea, but the machines that quilt mattress tops are about eight feet high and about 12 feet long. New they are about six figures. In the factory I retired from we had fork lifts that were rated at 1800 lbs. We had to rent a larger one to move these. Another home quilter or two and a helper may be a better solution until your business grows to support one of these beasts.

ReviewKid says

Juki has really some great industrial sewing machines that may not be found with other popular brands. Even with Brother or

Singer. You can check Juki DDL-8700 it is very popular as an industrial sewing machine and it has all the required features for fulfilling such purposes.

Adam Waddy says

Thank you for this post. I will be in the market for a new machine soon as my present sewing machine is on its last legs. I’ve always wanted a Juki so I will look at that brand when I’m ready. There are so many choices, I don’t want to make a hasty decision.

Sarah says

Hi Chie,

Thanks so much for this very informative review! I just bought my very own Juki 9000B and am loving it so far. I just wondered what type of thread you used in your Juki? I mostly sew on satins and chiffons too. Do you have a particular brand you use or weight of thread? I am struggling to find a thread I really like! Any advice would be fantastic!

Thanks!

Chie says

Hi Sarah! Yay for your new Juki! I hope you’ll enjoy having a sturdy, fast machine. I usually use thread weight #50-90. I prefer threads for stretch fabric even when I sew non-stretch fabrics like satin or organza. Hope this helps!

Sarah says

Hi Chie,

I never thought of using stretch thread – thanks for that tip! Do you have any recommendations on brands? There are so many it’s confusing! I have no sewing shops near me so I have to buy everything online which is annoying.

Also what needles do you use for that thread? I have some Organ Titanium that I’m using at the moment.

Sorry for all the questions and thanks so much for your help 🙂

Chie says

Hi Sarah! So sorry for my late response. I usually use resilon knit thread. Here is the link: http://global.rakuten.com/en/store/handcraft/item/594204/

Connie says

Please help. Can you use a commercial/industrial machine to sew clothing like you would a domestic machine? smaller thread and needle? I’m wondering whether I will purchase one machine to do all my sewing. I will be sewing costumes and some fabric is very delicate and some is leather.

Chie says

Hi Connie, I am not an expert in sewing machines, but I assume you can sew regular clothes with industrial sewing machine. I sew satin, chiffon, tulle, lace, all the fabrics you use to make wedding dresses with my industrial Juki.