So my friend texted me the other day to tell me that she received the 5th muslin and it fit!! I was super relieved to hear that. Now I know that my pattern fits her and it’s time to cut the final fabric! I was super anxious before I received the text from her. I was jittery, and kept checking my emails to see if she had sent word. I was so happy when she finally told me it fit her well.

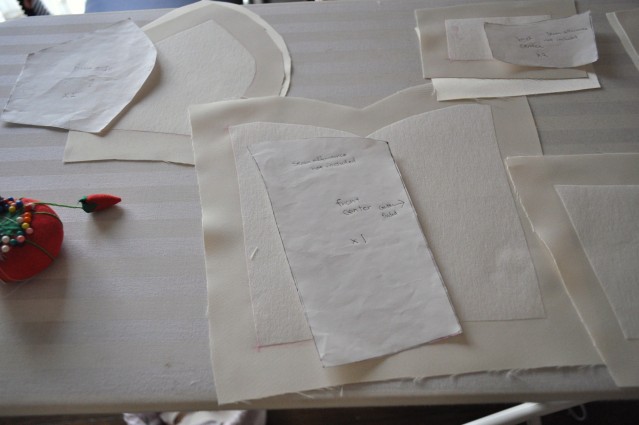

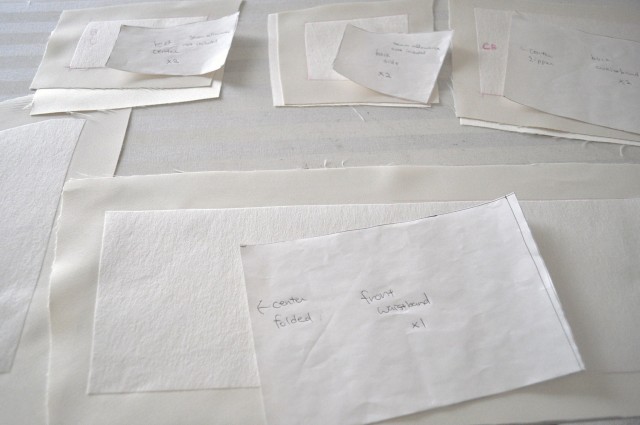

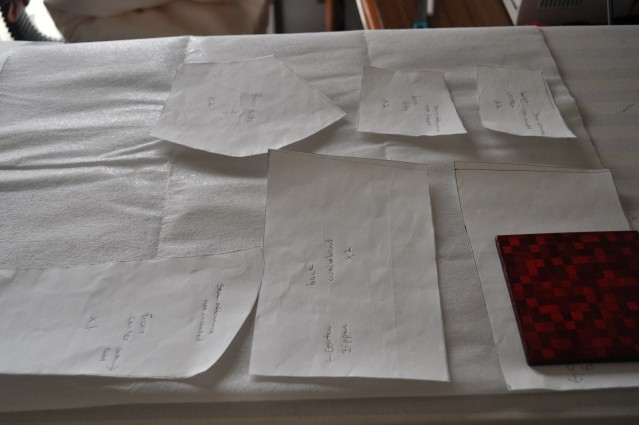

As I wrote in my previous post, I’m working on seam lines, instead of seam allowances. This way I get a more accurate fit.

I was so nervous about cutting the actual fabric! But I reminded myself that if I screw it up, I can always go to Nippori and buy some more. No biggie!

I made sure not to use pins inside the seam lines. I didn’t want any needle marks on the fabric. The fabric I worked on was easily scratched.

I cut out all the pieces for the top part of the dress – center front, front side, back side and center back. Then I ironed on the iron-on interface. After using the iron-on interface though, I kind of regretted using it and thought it would have been better to use muslin fabric to underline it.

I cut out all the pieces for the top part of the dress – center front, front side, back side and center back. Then I ironed on the iron-on interface. After using the iron-on interface though, I kind of regretted using it and thought it would have been better to use muslin fabric to underline it.

Readers, which do you prefer? iron-on interface or underline? I guess it depends on what you are sewing..any thoughts?

Read my progress on sewing wedding dress! :

Part 1 – Fabric shopping

Part 2 – Muslin

Part 3 – Another Muslin

Sewing Tool: Eyelet

Sewing Tool: Eyelet My Recent Antique Kimono Finds

My Recent Antique Kimono Finds fabric stash clean-up project

fabric stash clean-up project Mommy’s Diary: Cat Applique T-shirt and Easy Shorts

Mommy’s Diary: Cat Applique T-shirt and Easy Shorts

Meghan says

I have always preferred iron-on interfacing, but the more and more I read about underlining, I am considering converting over. Either way, I’m sure that this dress will be amazing. =D

Sue says

I definately would love to try underlining out. especially after finished sew retro class now. It was super great idea use muslin as a underlining later. I wanna bring this idea to make winter coat soon.

Sue says

forgot to say. You will create perfect dress for your friend. Don’t worry about iron on interfacing or underlining.

sarah says

I tend to use iron on interfacing but I’ve had a few mis-haps with it recently and now I’m keen to try underling instead.

i can’t wait to see this dress finished 🙂

Sarah says

Hello there!

Just a quick comment with a tip when using interfacing/fusing, from you pics there it looks as though you have used an non-stretch paperey like fusing? Is that so? (Sorry can’t remember the correct name for this type of fusing!) When I was working in fashion Industry we always used a stretch high-quality fusing such as whisper weft or sheer weft fusing on all fabric types, you can purchased this type of fusing in different weights from sheer to quite a heavy weight, this fusing fuses beautifully for just about every type of fabric I have used from silks to georgettes and heavy weight wools to. Because of the stretch nature of the fusing it strengthens the fabric giving it more body and weight but without the crinkly, stiff feeling that the other types create. It still retains the quality and characteristics of the fabric you are using. Does that make sense? Maybe have a look around and see what other types of fusing are available to you and buy a small amount and do a trial on sample fabrics to see the difference? (we also used to test fusings on different fabrics to see what will be the most appropriate)

I used to hate fusing before i knew about this type! Most sewing /fabric stores will sell this as a stretch fusing but its not to be only used for stretch fabrics!!! I know that alot of bridal places use this type of fusing to “Block” Fuse the whole amount of fabric (including the skirt) before cutting out the individual pieces as it prevents the fabric from creasing during wear and makes it really nice to sew and press aswell!

Just as a note I only use the whisper and sheer weft fusing on all my sewing projects and have great success with it!

Sorry for the rant, just quite particular about fusing as it does make such a difference to the finish of the garment and on a whole most home sewing places don’t really have the knowledge of the different types of fusing available and what is the best one for the job!

Also depending on the level of stability that you are requiring, you could also use a product called “Shapewell” it may be the same thing as what you guys are calling underlining though. At times we have used both the whisper weft fusing to the main fabric then the “Shapewell” stitched to the lining…

xxx

Chie says

hi sarah! thank you so much for sharing your insight! i learned a lot from you comment 🙂

yes, the one i used was very paper like thick iron on interface. i wasn’t all that pleased with the result. i wasn’t terrible, but i felt as though it could have turned out better and more smooth.

i’ve used stretch iron on interface, but i didn’t know you could use it for non-stretch fabric as well!

by the way, i love your pattern shop! i would love to make myself the shorts you have…adorable!

JEH, Esq. says

Yay! I was so glad to read that your friend’s muslin finally fit. Happy Sewing!

(BTW Excellent post Sarah! I learned a lot!)

Chie says

thank you!! im so glad that it fit her too!!

Dani says

Hey there! I am currently teaching myself to sew a wedding dress. Would anyone recommend not using interfacing at all? I have to buy some if so, but I am totally lost on what type to buy. Please help!!

Chie says

Hi Dani, I think it depends on what fabric you are using to make the dress. This post documents my very first wedding dress, so I didn’t know much. I used iron on interface, which I would not do now. When I use satin to make bodice now, I use muslin fabric (cotton) to underline, instead of iron-on. I like the finish much better. Depending on your fabric, silk organza might work better. Good luck!